News & Events

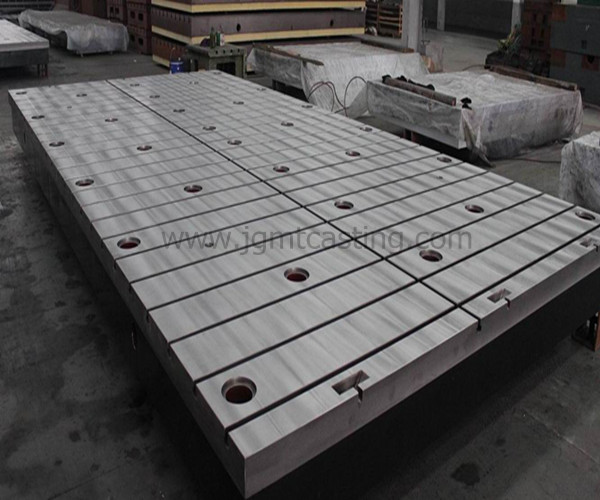

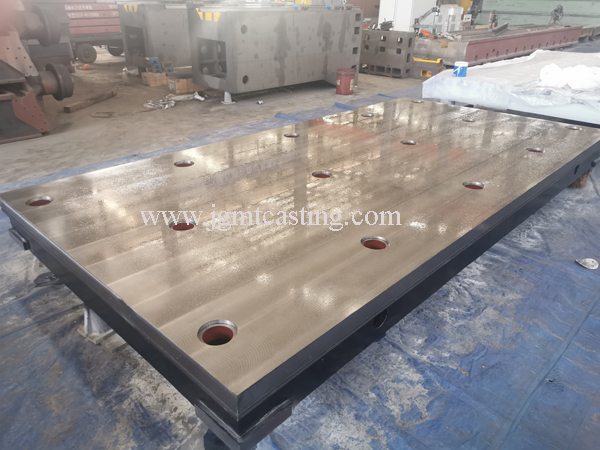

The important nodes in process of cast flat plate/machine table

Cast flat plate/machine table is made of pig iron smelted and poured into iron castings, and then made by sand falling, heat treatment, machining, scraping, painting, cleaning and other processes. It can be used for inspection, scribing, measurement, assembly, welding and other functions.Read more >>Welding technology-innovative welding platform

The welding platform of the welding workshop is a very important platform. The stability of the platform directly affects the welding effect, so the selection of the welding platform is very important.Read more >>Scraping of cast iron machine table

Scraping of cast iron machine table is an important method of finishing in machine manufacturing and repair.Read more >>The specific method of the ground anchor when installing the cast iron machine table

For some mechanical equipment, the number and shape of installation and use are specified in the equipment manual or design drawings, and the ground anchors are also included with the equipment. Therefore, the installation must be done according to the drawings.Read more >>The setting and placement of the leveling pads

The process and method of correctly placing the leveling pads on the surface of the concrete foundation before the equipment is installed in place. The leveling pad is also called the shim.Read more >>Inspect the casting cleaning process of the cast iron machine tables

Shaking out: The measuring tool castings can be squeezed out after being fully cooled, and the general requirement is not less than 3 hours. If the time is too short, surface chilling will occur and the hardness will be higher and cutting will be difficult.Read more >>