News & Events

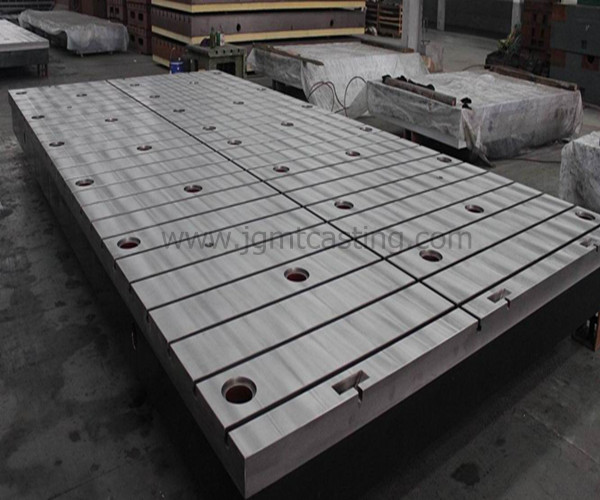

Why are there holes and T-slots on the working surface of the boring machine table?

The work platform of the boring machine will punch holes and T-slots during processing. The T-slots are used to fix the work piece, and the hole is used to clean the iron chips generated during the hole processing. Standard twist drills are generally used for drilling, and the drill bit will become dull after more use.Read more >>How is the high-precision cast iron base table processed?

High-precision cast iron base table need to be manufactured by manual scraping. The cast iron plate is manually scraped after being machined by the machine tool.Read more >>The difference between normalizing, annealing, quenching and tempering

The difference between annealing and tempering is: (simply put, annealing means that no hardness is required, and tempering still retains a certain degree of hardness).Read more >>New heat-resistant high chromium cast iron grate production process

1. styling Using the clay sand wet casting process, a box of 2 pieces, the upper box eats 75mm of sand, the lower box eats 60mm, and the surrounding sand eats 35mm. It adopts template shape, and the parting surface is sprinkled with quartz powder. It adopts a closed gate with two internal gates of 12mmx25mm and a straight gate of 60mm.Read more >>Technical conditions of sintering machine grate

Classification: The main materials of the grate are heat-resistant iron, heat-resistant high-chromium cast iron, ordinary cast steel, high-chromium-nickel heat-resistant cast steel, etc.Read more >>Cast iron bed plate production process

1. Make a model according to the cast iron flat drawing approved by the purchaser, and prepare the casting tooling (sand box, core iron), etc.Read more >>