Lost foam castings have high dimensional accuracy, generally CT4-6 (CT10-13 for sand casting and CT5-7 for die casting). Of course, due to the complex casting process, there are many factors that affect the dimensional accuracy, such as mold shrinkage, deformation and heating of the mold shell. Due to the linear change in the cooling process, the shrinkage of the alloy and the deformation of the lost foam casting during the solidification process, the dimensional accuracy of the investment casting is usually high, but its consistency needs to be improved (high temperature when used the size consistency of wax material investment castings has been greatly improved).

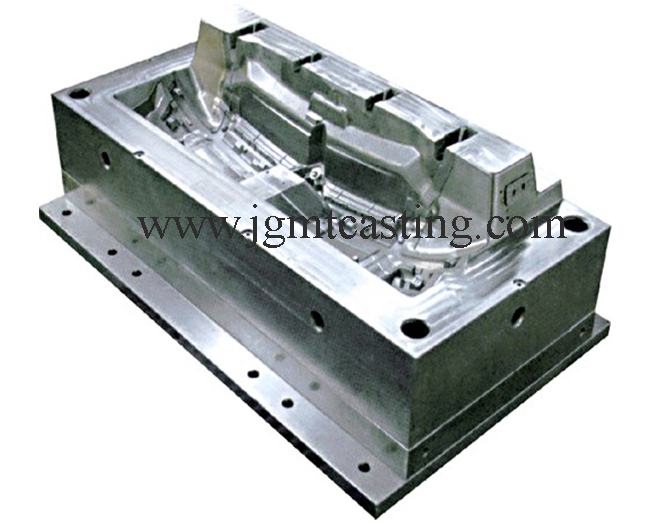

Automotive Stamping Die Mould

When the mold is rolled, the surface smoothness of the mold is relatively high due to the use of a press mold with a high cavitation surface smoothness. In addition, the mold shell is coated with a special adhesive and a refractory paint matched with a refractory material on the mold, and the inner surface of the cavity that is in direct contact with the molten metal has a high degree of cleanliness. Therefore, the surface roughness of investment castings is higher than that of general investment castings, generally reaching Ra.1.6 to 3.2μm.

The big advantage of lost foam casting is that because casting products have very high dimensional accuracy and surface finish, they can reduce machining work, and only need to leave a little processing power on the parts with higher requirements, or even Some casting products only have grinding and grinding surplus, which can be used without mechanical processing.

It can be seen that the use of casting methods can greatly save machine tool equipment and processing time, and can also greatly save metal raw materials. Another advantage of the casting method is that it can cast complex die castings of various alloys, especially high-temperature alloy lost foam castings. Like the blade of a jet engine, its streamlined periphery and cooling cavity can hardly be formed by machining technology. Using investment casting technology to produce can be mass-produced, which not only ensures the consistency of investment castings, but also avoids the stress concentration of residual blade lines after machining

Jinggong Measuring Tools Producing Co., Ltd is specializing in manufacturing and exporting all kinds of cast iron products,especially for cast iron floor plates, cast iron surface plates, cast iron clamping plates, cast iron angle plates, cast iron box table and other machine tool castings. Our engineering enables us to design the cast iron plates and tables according to DIN Standards, Indian Standards and Chinese Standards, machining by CNC machine tools and install in the world market.