According to the structure of the cast iron clamping table, the cast iron plate is divided into rib plate type and box type. The reasonable design of the thickness, height and number of passes of the ribs plays an important role in ensuring the accuracy of the cast iron platform. Because the cast iron platform is provided with reinforcing ribs, the structural strength of the cast iron mold can be improved, which is beneficial to prevent it from cracking due to excessive internal stress.

(1).jpg)

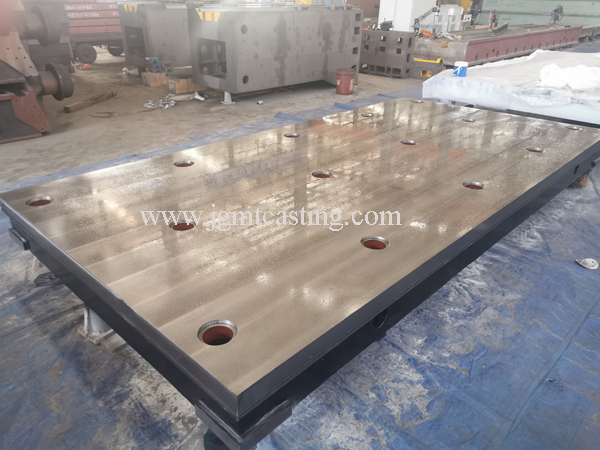

cast iron clamping table

The cast iron clamping table is suitable for all kinds of inspection work. The reference plane for precision measurement is mainly used for the reference plane in the inspection and measurement of mechanical workpieces to check the dimensional accuracy or behavior deviation of parts.

Introduction of vibration aging of cast iron clamping table:

The material is high-strength cast iron HT200-250, and the hardness of the working face is HB160-210. The product has stable accuracy and good wear resistance. It is suitable for all kinds of inspection work. It is a reference plane for precision measurement and is used as a reference for machine tool mechanical measurement to check the dimensional accuracy or shape and position deviation of parts, and make precision marking.

The vibration aging treatment effect of cast iron clamping table and cast iron plate is stable and reliable. For large cast iron platform and cast iron plate workpiece, vibration aging can avoid a series of disadvantages caused by poor thermal aging quality controllability, and greatly improve the processing quality.

When the material of the cast iron welding platform exceeds the acceptance conditions and cannot be remedied, or the casting cracks during solidification, cooling or heat treatment, it should be scrapped.

The welding platform is used for the basic plate of the riveting process. There are holes and T-slots on the working surface. The holes are mainly used to clean some iron slag and welding waste during riveting. The T-slots are mainly used to fix the welding parts. Of course, the welding plate/platform is also flat, that is, no holes and no grooves.

cast iron smooth/flat plate

There are many ways to prevent the cast iron assembly platform from rusting, which are divided into short-term and long-term.

1. After the work is completed, use anti-rust oil to wipe the running and outside parts of the machine.

2. Maintain the sanitation of the processing workshop and keep it clean to prevent dust from entering the workshop. At the same time, reduce the humidity in the workshop, dehumidify the warehouse in summer, and avoid corrosion due to low temperature re-frost in winter.

3. If it is not used for a long time, anti-rust measures should be taken to avoid large areas of rust and sometimes even damage the plane of the cast iron platform. The cast iron platform should be cast iron platform with the strength of HT400-300, the hardness of the mission surface is HB270-250, and the cast iron platform that has undergone more than two aging treatments. Such cast iron platform has stable properties and good wear resistance.

There are the following points to avoid the deformation of the cast iron platform:

1. The cast iron platform will be deformed due to temperature changes, so when using the cast iron platform, you must pay special attention to the temperature change at the place of use.

2. Bumping, crushing, beating, etc. are all deformations that can constitute the cast iron platform;

3. Putting an overweight workpiece on the platform will bend the cast iron platform;

4. A cast iron platform that does not meet the standard is selected.